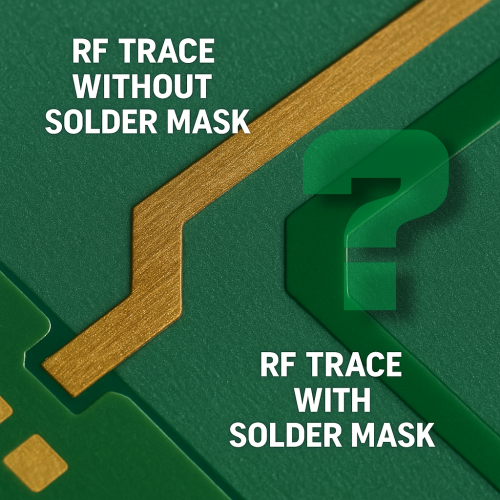

When designing RF PCBs, every small detail can have a significant impact on signal performance. One frequently debated practice is whether to remove solder mask over RF traces. Let’s explore why many RF designers choose to leave RF traces exposed, and when it might be the right choice for your design.

Why Remove Solder Mask on RF Traces?

1. Consistent Impedance

Solder mask changes the effective dielectric constant above the trace, which alters the trace impedance. This might not be significant at lower frequencies, but at RF and microwave frequencies, even small impedance variations can lead to reflections, losses, and degraded signal integrity. Removing the solder mask ensures the impedance stays as close as possible to the designed value.

2. Reduced Dielectric Loss

Solder mask materials generally have higher dielectric losses compared to the PCB core material (such as Rogers, FR4, etc.). Exposing the copper trace reduces the amount of lossy material interacting with the RF signal, thus minimizing signal attenuation.

3. Improved Repeatability

Manufacturing tolerances on solder mask thickness can vary, introducing inconsistencies in impedance across different boards. By removing solder mask entirely from RF traces, designers eliminate one more source of manufacturing variability.

4. Easier Probing and Tuning

During development and testing, having exposed traces makes it easier to probe signals or adjust tuning elements directly on the copper without the need to scrape off the mask.

Potential Downsides

Oxidation: Exposed copper is prone to oxidation over time, which can affect solderability and long-term reliability. A common solution is to apply surface finishes like ENIG (Electroless Nickel Immersion Gold) or silver to protect the copper.

Mechanical Protection: Solder mask provides some protection against scratches, contamination, and handling damage.

Aesthetic Concerns: Fully exposed copper can tarnish and change color, which may be undesirable for cosmetic reasons.

When Should You Remove Solder Mask?

High-frequency designs (above 1 GHz)

Sensitive RF front-end circuits

Controlled impedance transmission lines

Antenna traces

Designs where maximum repeatability and minimal loss are critical

Conclusion

Removing solder mask over RF traces isn’t necessary for all designs, but for high-performance RF circuits, it can provide measurable benefits in impedance control and signal integrity. Always weigh the pros and cons based on your specific application, frequency range, and reliability requirements.